Can Tyres Be Sustainable?

Kwik Fit | Thursday 3rd May 2018 3:00pm

Now more than ever, environmental friendliness is at the forefront of society’s consciousness – and the sustainability of tyre development, tyre recycling, and technology are no exception.

At Kwik Fit, we are often asked questions about the sustainability of the tyres we offer and the manufacturers who create them. The environment is a subject that we have given much thought to, and take very seriously. The same is true of premium tyre manufacturer, Continental.

With over 140 years experience in developing cutting edge tyre technology, Continental is responsible for introducing the essential tyre treads we now all take for granted, it should not come as a shock to learn that Continental are leading the way when it comes to the sustainability of tyres. A significant aspect of their sustainability ethos is Continental’s focus on resource conservation and fuel economy (including the reduction of CO2 emissions), without compromising their core aims of safety and performance.

How can I recycle my tyres?

Every time you buy new tyres from Kwik Fit, we include a small fee for tyre disposal. Your old tyres are then sent to our tyre recycling facility where they are turned into rubber granulate or rubber crumb which can be used to make new rubber products such as artificial sports pitches.

Resource conservation & alternative material development

Some of the world’s leading experts (from a diverse range of fields and specialisations) are employed in Continental’s numerous laboratories around the world. Continental’s experts are engaged in the research and development, testing, and manufacturing processes in order to help create Continental’s Tyre of the Future.

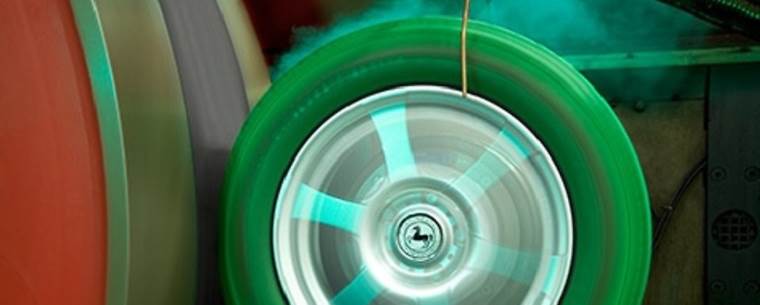

In their mission to design and produce more energy-efficient, eco-friendly and sustainable tyres that encompass manufacturing, driver usage, and recycling phases of the tyre life cycle, Continental experts, like Dr. Fred Waldner, are exploring all possible options. His laboratory focuses on the mixing and testing of rubber compounds, which has led to the exploration of some very interesting material combinations.

According to Dr Waldner “Every year, several thousand samples are produced here, drawing on more than 1,500 different materials.

“You can’t replace all of the natural rubber in a tyre with synthetic rubber. The technical advantages and unique properties of the natural product are simply too important. Apply heat to natural rubber and it can be shaped; when it cools down it remains elastic, can be stretched, and will then return to its original shape. The rubber made from this natural product can be elastic or energy absorbing, depending on the composition of the material.”

Dandelion latex, a natural alternative to rubber, has the potential to move from laboratory experimentation to application in the real world. Originally mixed in Dr. Waldner’s lab, and developed in partnership with the Fraunhofer Institute for Molecular Biology and Applied Ecology (IME), dandelion rubber shows incredible promise, with the possibility of becoming a commercially viable alternative to the natural rubber currently harvested from the world’s rubber tree plantations. When this incredible initiative was announced in 2014, it won the prestigious and highly sought after Greentec Award.

For a long time now, natural habitats have been under strain as they have been destroyed to make way for rubber plantations. Initiatives like Continental’s dandelion latex will help to stop the tyre industry from being too reliant on rubber tree plantations, and have a significant impact on reducing the global deforestation resulting from the need to grow rubber.

As a result, in the near future, it’s possible that we could see sustainable dandelion plantations located near the tyre making facilities. This will help to combat rainforest deforestation and the destruction of the environment.

Are dandelion tyres a viable alternative?

So how could this new alternative material become a genuine option for manufacturing sustainable tyres? The goal is to use the natural latex obtained from the roots of the dandelion as a commercially viable substitute for natural latex from rainforest plantations.

The exciting agricultural potential of growing dandelions is that they can be cultivated on land that food crops cannot be planted on, such as that utilised for industrial developments, including tyre manufacturing plants or ‘plantations beside the tyre plants’.

In Central Europe this makes strong economic and ecological sense, with the advantages of this model including significantly reduced transportation distances between material harvesting and material processing. This would lead to a reduction in CO2 emissions during this part of the tyre manufacturing process. A further benefit of this is that if we no longer need to enforce monocultures in rainforest regions, the destruction of these vital habitats can be reduced.

The ‘plantations beside the tyre plants’ model offers a potential commercial benefit to UK drivers too. By using a more manageable, sustainable alternative material, Continental hope to experience some immunity from the soaring prices that often occur in the global rubber market. Increased demand often results in an increase in cost, and that ends up affecting all motorists.

As up to 30% of the rubber used in car tyres currently comes from the plantation tree Hevea brasiliensis, dandelion rubber could potentially decrease this financial burden.

Playing your part: Recycle your tyres

While it’s essential for premium tyre manufacturers, like Continental, to continue spearheading the quest to achieve sustainable tyres, it’s important to remember that we all have a part to play. As a car owner, you too can make a significant contribution to the challenges facing the environment. A good way to do this is to recycle your tyres.

Since the introduction of the 2006 EU Landfill Directive, it is illegal to place end-of-life tyres within landfill sites. Instead, all tyres need to be either recycled, or reused in some way. Of course, fly-tipping is also not an acceptable way to dispose of tyres.

The recycling process is fairly challenging, since tyres are made up of different amounts of steel, rubber and textile. Firstly, end-of-life tyres are granulated, so as to ensure that the various materials that constitute an individual tyre can be successfully separated. Next, the tyres are shredded into what is commonly referred to as ‘rubber crumb’. This core material has many uses, including for the construction of carpet underlay, sports surfaces, pitches and running tracks, children’s playground safety mats, drainage systems, and roof tiles. The rubber crumb can also be utilised to create rubberised asphalt road surfaces.

If you browse the internet for “tyre collection and recycling service”, you should find a large number of tyre recycling options in your local area. Alternatively, if you purchase new tyres from Kwik Fit, we can recycle your old tyres for you.

Fitting tyres with low rolling resistance will help reduce your fuel consumption

Premium tyre manufacturers, like Continental, have developed a range of tyres that offer low rolling resistance. Fitting these tyres results in reduced fuel consumption, as well as lower CO2 emissions. This is another way in which Continental are contributing to the sustainability of tyres, and offers UK motorists a chance to do their bit for the environment. This could also have the additional bonus of saving some money too.

Take a look at Continental’s highly regarded ContiEcoContact™ 5, which provides drivers with optimised rolling resistance, without compromising on high braking safety (over short braking distances) on wet roads. This excellent tyre ranks very highly for both fuel efficiency and wet weather braking on the EU Tyre Label.

Ask our tyre experts

If you’re unsure about sustainable tyres and want to benefit from our expert knowledge, get in contact with one of our tyre professionals. Our dedicated team can provide you with experienced, impartial advice, as well as the best tyre fitting solutions, and more. Find your local Kwik Fit centre today.

Any facts, figures and prices shown in our blog articles are correct at time of publication.

Featured Articles

Is it Illegal to Drive With One Headlight?

Saturday 19th July 2025

Wondering if it’s illegal to drive with one headlight? Learn about the safety risks and penalties of illegal blown bulbs and why you should fix them promptly.

Air Con in EVs & Hybrids: Experts Answer Your Questions

Monday 30th June 2025

Does air con drain EV batteries? Can you use the air con while charging an electric car? Find out the answers to these questions & more from Kwik Fit’s experts.

Why Is Your Car Making a Noise? Fixes & Tips

Friday 13th June 2025

When your car starts making unexpected noises, it can certainly be quite disconcerting; it may be nothing to worry about, but here’s what you need to know.